Ancient steel manufacturing process was carried out in bloomeries and crucibles. The Industrial Revolution brought about the development of large scale methods of producing steel. Steelmaking involves removal of impurities such as nitrogen, silicon, phosphorus, sulphur and carbon from the sourced iron, as well as alloying other elements such as manganese, nickel, chromium, etc., to produce different grades of steel.

Modern steel industries use recycled materials as well as traditional raw materials such as iron ore, coal and limestone. Almost all the steel manufactured today uses 2 processes-basic oxygen steelmaking (BOS) and electric arc furnaces (EAF).

Step 1: Iron-Making

This is the first step in the manufacturing of pure steel. In this step, the raw materials like iron ore, coal and lime are melted in a blast furnace. Thisresults in the formation of molten iron, also known as hot metal, which still contains 4-4.5% of carbon and other impurities, which makes it brittle. These have to be subsequently removed.

Lorem ipsum dolor sit amet. Sed omnis reprehenderit est officiis nesciunt non possimus animi? Nam doloremque Quis qui quam iste non sint magnam non corporis harum sed illo quisquam.

Step 2: Primary Steel Making

The remaining impurities are removed by either BOS or EAF methods.

In the BOS method, recycled or scrapped steel is added to the molten iron in a convertor. Oxygen is blown through the metal at high tem- peraturesand this reduces the carbon content to about 0-1.5%.

In the EAF method, scrap steel is fed through high-power electric arcs to melt the metal and convert it into high quality steel. The steel that is obtained at the end of this step, by either of the methods, is called raw steel.

Step 3: Secondary Steel Making

This step involves treating the raw steel in different ways to get different grades of steel. This may include addition or removal of certain ele- ments, and / or altering the temperature and the production environ- ment.

Sit rerum galisum ex sequi nobis est Quis deserunt hic molestias deleniti eum reprehenderit illo? Nam adipisci vero in voluptatem fugit et sunt tem- pora aut cupiditate esse ut voluptatibus.

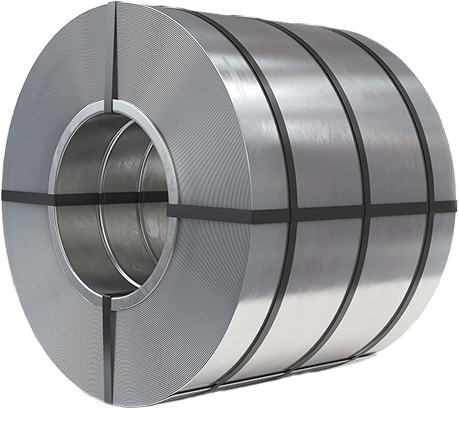

Step 4: Secondary Forming

The final step of the steel manufacturing process creates the final shape and properties of the steel. Secondary forming is accomplished with different methods such as shaping (cold rolling methods), ma- chining (drilling), joining (welding), coating, heat treatment, and sur- face treatment. At the completion of step 6, the steel is fully shaped, formed, and ready for use and processing in various applications.